The tool shop specializes in design, manufacture and putting into operation of forming tools (punching, drawing, bending and combined tools), moulds for injection of thermoplastics and two-component plastics, measuring fixtures, automation for injection moulding of plastics and for spare parts.

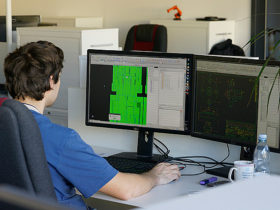

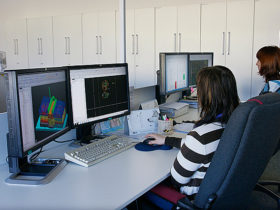

The designing department is one of the key departments at FOREZ. 12-15 designers prepare models of moulds for injection of plastics, dies for stamping of metals, fixtures and equipment for automation, and 2-4 draughtsmen/draughtswomen prepare production documentation (workshop drawings) based on the models. Moulds and dies are designed based on moulding and stamping models delivered by customers. In the field of plastics, besides standard moulds, our designers are experienced in multi-component moulds, moulds for rubber injection, multistage moulds, and moulds with nitrogen cores (GID).

In the field of metal processing our designers have experience with single-position tools (cuts, bends, draws), progressive dies for transfer presses – mainly deep-drawn parts, tools for the so called Talo presses (Bihler), tools for stamping at high-speed presses, tools with threading units, tools with screwing units, riveting tools, … Concerning equipment for automation, our designers prepare manufacturing documentation of gripping heads for press robots, measuring devices for stamping measurement (dimensional, functional and electrical measurement), automation for presses – preparation of contacts for embedding, contact bridge cutting through.

Siemens NX 8 CAD system (formerly Unigraphics) is used for creation of models and drawings. Simcon Cadmould CAE system is used to analyse injection of plastics. This software allows to better assess beforehand the gate location, cold joints, tension conditions in the moulding, …, but in particular the part deformation. Thanks to this fact, already at the stage of design measures can be taken or recommendations can be given for minor changes to the moulding so that complicated debugging only at the stage of manufactured mould can be avoided. The drawings are created at the Xerox large format multi-functional equipment fitted with a drawing folding device.

The Production Technology department is responsible for technological engineering of projects to be run both in the stamping shops and in the plastic moulding shops of FOREZ. Individual technologists of the Production Technology department prepare tools, moulds and equipment to assure as smooth flow in the series production as possible. 6-7 technologists work in the production technology department for the plastic moulding shop. 3-4 technologists work in the production technology department for the metal stamping shop. In the field of plastics our technologists are experienced in projects concerning standard moulds as well as multi-component moulds, multistage moulds, and moulds for rubber injection, … Additionally, we are experienced in preparation of projects with a various grade of automation, e.g. s linear robots, one or two 5-axis KUKA robots, automatic inspection of parts, automatic assembly, automatic final shaping and inserting of contacts, … In the field of metal processing our technologists are experienced in single-position tools (cuts, bends, draws), progressive dies, tools for transfer presses – mainly deep-drawn parts, tools for the so called Talo presses (Bihler), tools for stamping at high-speed presses, tools with threading units, tools with screwing units, riveting tools, …

The tool shop capacity is approximately 2,100 fitting and assembly hours per month. Corresponding machine, technological and designing capacities are also available.

The tool shop is a holder of the quality management certificate according to ČSN EN ISO 9001:2008, ČSN EN ISO 14001:2005.

The tool shop has the following technologies available

- Programming and modelling in NX 7 (formerly Unigraphics)

- 3-axis CNC milling for maximum dimensions of 1250x600x700

- 5-axis CNC milling for maximum dimensions of 600x600x500, weight up to 400kg

- Wire cutting for maximum dimensions of 800×500 and die height of 520mm

- Electroerosion sinking for maximum dimensions of 500×350 and height of 400mm

- Electroerosion burning-out for maximum work-piece height of 300mm and weight of 50 kg

- HSC CNC machining – machining of graphite and copper electrodes, machining of hardened materials do 60 HRC.

- CNC turning up to a diameter of 160mm

- Surface grinding up to dimensions of 1200x800mm and height of 500mm

- Form (point) grinding – AMADA machine – Japan

- Cylindrical grinding up to the diameter of 250mm and length of 700mm

- Jig boring for maximum dimensions of 700x400mm and height of 500mm

- Standard turning up to the diameter of 250mm and length of 1000mm

- Standard milling up to dimensions of 600x400x400

- Fitting and assembly of tools, moulds and fixtures with a weight of up to 6,000 kg.

- 3-axis coordinate measurement for maximum dimension of 2000x900m and height of 600mm

- Optical camera measurement at the 3-axis Vertex machine for maximum dimensions

- of 200x150mm and height of 100mm, weight of 10kg